Despite its high efficiency, LEDs face the issue of high heat dissipation densities during operation. For instance, a LED, with an electrical power rating of 1 W and an efficiency of 90 percent, produces a surface heating power density of 100 kW/m2. This corresponds to approximately twice the heating power density of a commercially available cooking plate. On the one hand, high operating temperatures have a negative effect on the lifetime of the LED (the lifetime decreases exponentially with increasing temperature); on the other hand, they cause an undesirable colour change in the LED in the long term.

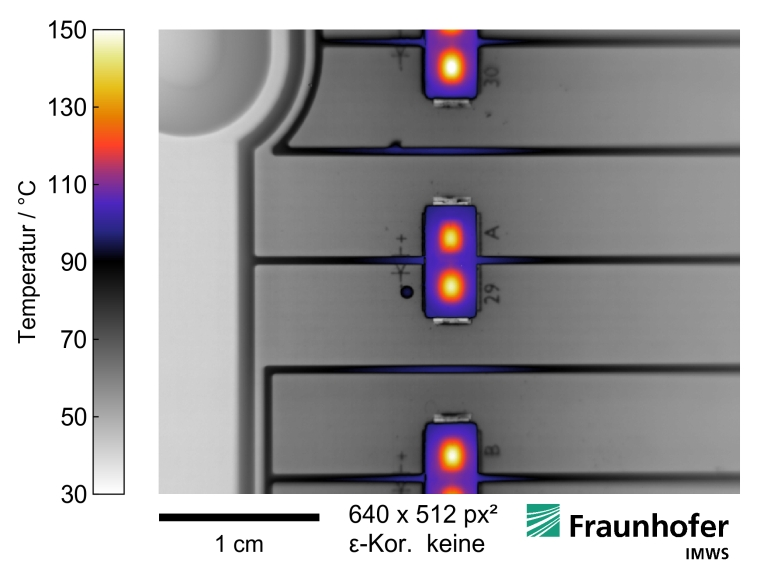

With the help of infrared thermography, the surface temperature of LED modules can be determined in a contactless and spatially-resolved manner. It is possible to identify the areas of the component which are subject to a higher thermal load. Often, the regions of interest are not directly on the surface, but are covered by other materials such as encapsulation materials or domes, which are only partially transparent to infrared light. To characterize the transmittance of these materials in the infrared spectral range, Fourier transform infrared (FTIR) spectroscopy is used to determine the influence of different materials on the thermography measurement. To be able to map hotspots within a LED package, a more accurate spatial resolution is required. For these measurements, an infrared microscope can be used at the Fraunhofer Application Center, which enables lateral resolutions in the range of a few micrometres.

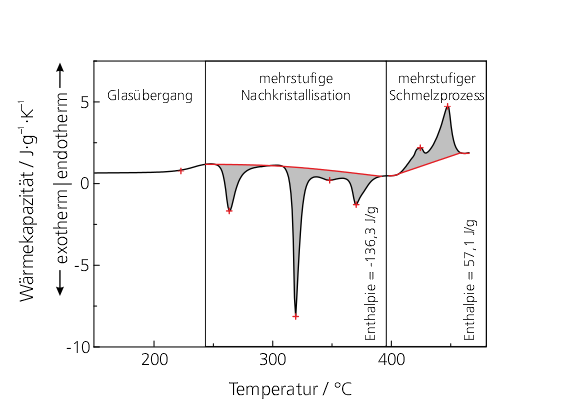

For the theoretical description of the heat transfer within a component, the heat capacity, the thermal conductivity, and the geometry of the materials and components involved must be known. Calorimetric and microscopic measuring methods are available at the Fraunhofer Application Center. The results of the investigations can be used to enhance the composition of the components in order to increase their efficiency and operational lifetime.