Phosphors based on lanthanide-doped glasses hold the potential of increasing the operational lifetime of white light-emitting diodes along with ensuring a more stable colour impression over the course of the lifetime of these LEDs. These luminescent glasses are characterized by an increased chemical and thermal stability. To further optimize white LEDs, the right combination of LED and phosphor is crucial. Terbium and europium are particularly suitable for use in lighting technology. They have an intense emission in the green (terbium) or red (europium) spectral ranges under ultraviolet or blue light excitation. When properly combined with a blue LED, a white light impression can be achieved. They also exhibit an intense emission, even at high temperatures of 150 °C during the operation of an LED. The thermal stability of the glass-based phosphors, developed at the Fraunhofer Application Center is above that of the conventional yellow phosphor of white LEDs, Ce: YAG.

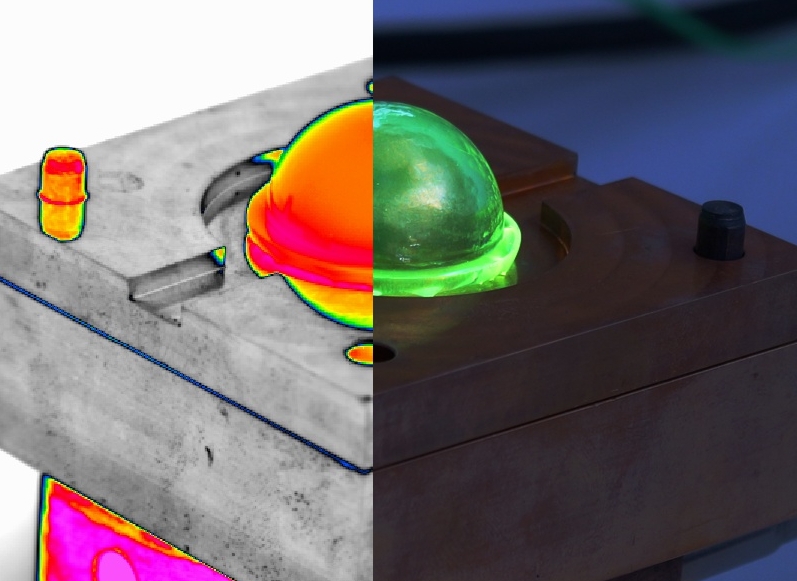

An often overlooked aspect of the thermal load of LED devices is the heat development within the phosphor itself. In the light conversion process, high-energy blue light of the primary LED is converted into low-energy (for example, yellow) light. The resultant energy difference (Stokes shift) is dissipated as heat. The heat output in the conversion from blue (450 nm) to yellow (570 nm) light represents more than 20 percent of the irradiated light output. The temperature of the phosphor surface can be recorded in a spatially- and time-resolved manner using an infrared camera. From the heat flow density in the glass, the total heat output released in the glass can be determined by means of thermographic imaging.