Research Project »HipE«: Laser Light Sources for Headlamps

As part of the research project HipE (highly innovative pixilated phosphors for laser-based emissions in headlamps), HELLA GmbH & Co. KGaA, a globally leading supplier of lighting and electronic products for the automotive industry, and the Fraunhofer Application Center for Inorganic Phosphors in Soest, are developing a prototype for high-definition headlamps with laser light source. The project started in March 2016 and is co-funded by the European Regional Development Fund (ERDF) over a period of three years.

Reducing installation space, increasing efficiency, improving light quality and safety – headlamp requirements are constantly on the rise. For meeting them, high-definition systems are becoming ever more frequent. Especially laser light sources have become very important. They are not just efficient in that individual light pixels can be activated as needed, but they also have a particularly high luminance. More light exits from a smaller light surface. This means that installation elements, such as reflectors, can be smaller, therefore allowing a more compact construction design.

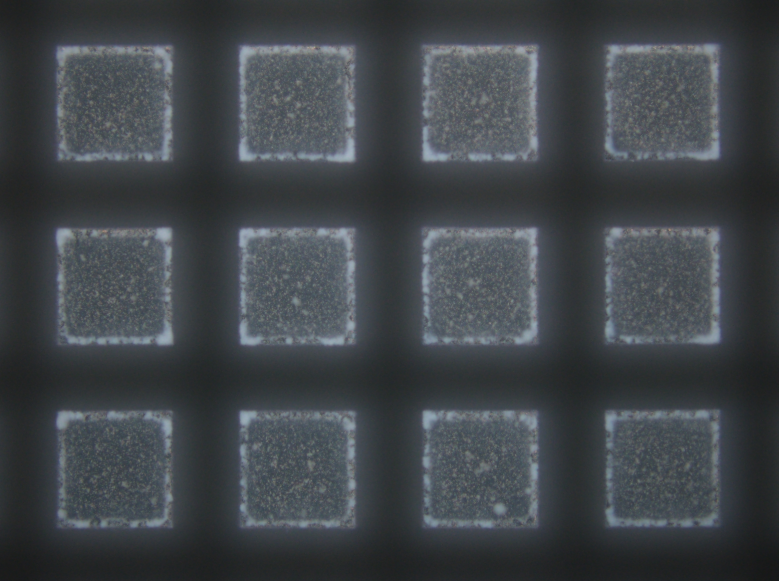

In order to apply adaptive functions to the road, i.e. headlamp light that automatically adjusts to the traffic and ambient lighting conditions, such as glare-free high beams, it is initially necessary to transform the blue short-wave laser radiation into white broadband radiation. The Economic Commission for Europe (ECE) regulates light color in Europe. The conversion of blue into white radiation occurs via phosphors. In the context of the HipE project, the Fraunhofer Application Center for Inorganic Phosphors tests various materials in view of their suitability – i.e. regarding their conversion characteristics and heat propagation – and then optimizes them. HELLA is developing a new mechatronic-optical concept for the construction of a complete headlamp module. The lighting and electronics expert for example checks, which optical systems are suitable for meeting the requirements for a more compact design and greater efficiency. Furthermore, HELLA is designing a demonstrator, i.e. an illustration model containing the new components. The ultimate goal consists in pushing the technologies developed during the project toward series production readiness.